In order to achieve a stable and correct connection of an optical connector, the contacting end faces must have an appropriate shape, so precision measurement of the end face shape is essential.

The MAX+/WIZ+ series optical connector end face 3D shape measurement system is a non-contact interference microscope that conforms to IEC international standards and automatically measures the end face shape of single-core and multi-core connectors.

In addition to its high measurement accuracy and ease of handling, its compact housing and speedy measurement make it possible to improve work quality at optical connector manufacturing sites.

* For measurement, a separate PC and a mounting jig according to the connector type are required. Please check the following operating environment for the operating environment of the PC.

Download materials

| Optical connector end face three-dimensional shape measurement system MAX+/WIZ+ Series |

download |

|---|

feature

1.Compact and lightweight housing

The housing has a compact design that can be installed in a smaller space than a B4 notebook, and weighs less than 4kg *, making it easy to carry.

*MAX-Quantum only weighs 4.8kg

2. Can be measured with a general-purpose PC

Just install the measurement software and driver on a standard Windows PC and you can start measuring right away.

3. Speedy display of clear images

4. Abundant mounting jigs

5. No anti-vibration table required

Since the housing has been carefully vibration-isolated, there is no need for an anti-vibration table, and it can be installed anywhere.

6. No setting required

Due to the use of precision ground mounting jigs, there is almost no need for adjustment work such as troublesome calibration.

7.AF (autofocus) function

The MAX+ and WIZ+ series have a built-in AF function that eliminates the need to manually focus for each measurement, making work more efficient.

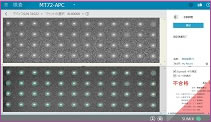

8. Achieves high reproducibility in multi-core measurement

Sumix's unique latest technology SideView (measures the angle of the guide pin from the side) enables even higher accuracy and reproducibility of measurement. In addition, since there is no need to hold down the connector and it is possible to fix the connector only by inserting the butt, it is easy to incorporate into an automated line.

Model selection points

You can choose the model according to the purpose of measuring the connector end face.

Single-core/multi-core dual use

| Model number | Performance | function | |

|---|---|---|---|

| field of view | resolution | ||

| MAX-Quantum | Big | High |

|

| MAX-QM+ | Big | During ~ |

|

Resolution High: Less than 2 μm/Medium: 2 μm to less than 3 μm/Low: 3 μm or more

| Model number | MAX-QM+ | MAX-Quantum | ||

|---|---|---|---|---|

| Measurement time for 1 terminal *1 | 1 second (single core) 3 seconds (MT12 core) |

1.4 seconds (single core) 7 seconds (MT12 core) |

||

| shape letter Measurement Fixed |

Repeatability CF/ Repeatability CR (SC/PC) *2 |

curvature radius (%) | 0.04/0.05 | 0.002/0.002 |

| Fiber height (nm) | 0.1/0.4 | 0.4/0.4 | ||

| Eccentricity (μm) | 0.04/1.1 | 0.02/0.55 | ||

| Repeatability CF/ Repeatability CR (MT12) *2 |

curvature radius (%) | 0.9/1.2 | 0.9/1.2 | |

| Fiber height (nm) | 0.8/1.1 | 0.8/1.1 | ||

| Ferrule angle (deg) | 0.0004/0.01 | 0.0003/0.01 | ||

| ※1: | The measurement time depends on the end face condition of the object to be measured and the performance of the PC. |

| ※2: |

Repeatability CF is the numerical value at 1Σ when the reproducibility is measured 30 times without inserting/removing the optical connector. Repeatability CR is a numerical value at 1Σ when the optical connector is inserted and removed for each measurement and the reproducibility is measured 30 times. Only MAX-Quantum uses SC/APC for single fiber data. |

Single fiber only

| Model number | Performance | function | |

|---|---|---|---|

| field of view | resolution | ||

| MAX-QS+ | During ~ | High |

|

| WIZ-QS-110 | small | During ~ |

|

Resolution High: Less than 2 μm/Medium: 2 μm to less than 3 μm/Low: 3 μm or more

| Single fiber only | ||||

| MAX+ series | WIZ+ Series | |||

| Model number | MAX-QS+ | WIZ-QS-110 | ||

| Measurement time for 1 terminal *1 | 2 seconds (single core) | 1.5 seconds (single core) | ||

| shape letter Measurement Fixed |

Repeatability CF/ Repeatability CR (SC/PC) *2 |

curvature radius (%) | 0.1/0.16 | |

| Fiber height (nm) | 0.3/0.4 | |||

| Eccentricity (μm) | 0.02/0.6 | |||

| ※1: | The measurement time depends on the end face condition of the object to be measured and the performance of the PC. |

| ※2: |

Repeatability CF is the numerical value at 1Σ when the reproducibility is measured 30 times without inserting/removing the optical connector. Repeatability CR is a numerical value at 1Σ when the optical connector is inserted and removed for each measurement and the reproducibility is measured 30 times. |

Measurable ferrules and connectors (requires optional mounting jig)

| Single fiber only | Single-core/multi-core dual use | |||

| MAX+ series |

WIZ+ series |

MAX+ series | ||

| Model number | MAX-QS+ | WIZ-QS-110 | MAX-QM+ | MAX-Quantum |

| ST, FC, SC (PC and APC) |

○ | ○ | ○ | ○ |

| MU, LC (PC and APC) |

○ | ○ | ○ | ○ |

| E2000 (PC and APC) |

○ | ○ | ○ | ○ |

| MIL-ST (M83522/16, MIL-C-83522) |

○ | ○ | ○ | ○ |

| M29504/14 (MIL-PRF-29504/14) |

○ | ○ | ○ | ○ |

| SMA 905 | ○ | ☓ | ○ | ○ |

| MT-RJ (PC and APC) |

○ | ☓ | ○ | ○ |

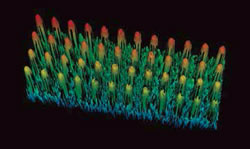

| MT12-MT72 (PC and APC) |

☓ | ☓ | ○ | ○ |

| MT16, MT32 (PC and APC) |

☓ | ☓ | ○ | ○ |

| MTP/MPO (PC and APC) |

☓ | ☓ | ○ | ○ |

| MTP/MPO (12-72 fiber and 16-32 fiber; PC and APC) SVF mount compatible |

☓ | ☓ | ○ | ○ |

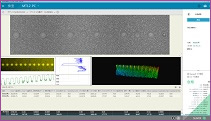

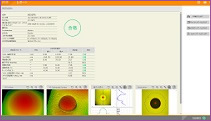

Functions and features of shape measurement software [MaxInspect]

Easy-to-use interface

* Language can be selected from English, Chinese, and Japanese. (The left figure is a Japanese screen)

Designed for mass production

*Foot pedal switch is optional.

Enhanced report output function

Automatic scratch detection function

* Not compatible with WIZ-QS-110/MAX-QM+

Operating environment

| Compatible OS | Windows 10 |

|---|---|

| CPU | intel Core i5 (Intel Core i7 recommended) |

| memory | 4GB or more |

| interface | USB3.0 |

| Measurement result output | ・Excel 2010 or later ・HTML |

*: The operating environment is subject to change without notice.

Specification

| Single fiber only | Single-core/multi-core dual use | |||

| MAX+ series | WIZ+ Series | MAX+ series | ||

| model number | MAX-QS+ | WIZ-QS-110 | MAX-QM+ | MAX-Quantum |

| light source | Green LED (530nm) | |||

| external interface | USB3.0×2 or DC jack for power supply x 1 and USB3.0 x 1 |

|||

| weight (kg) | 3.9 | 3.9 | 3.8 | 4.8 |

| External dimensions (H×W×L mm) | 103×137×183 | 150×120×90 | 103×137×183 | 181×213×117 |

Standard accessories

| Product name | quantity |

|---|---|

| Hard case for storing measuring instruments | 1 piece |

| Body calibration mount (flat standard mount) | 1 piece |

| USB memory (measurement software [MAXInspect], license file included) | 1 piece |

| USB cable | One |

| AC adapter | 1 piece |

close up

close up