Feature

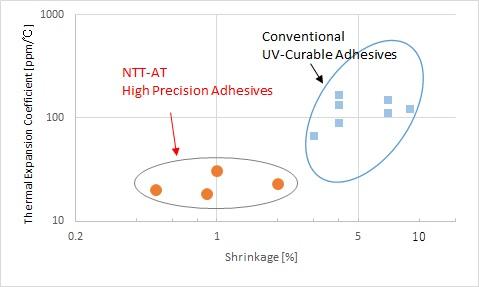

- Adhesive fixation on the order of submicrons is possible because there is very little change in fixing position due to curing or temperature changes.

*Low coefficient of thermal expansion (40 ppm/°C or less)

- AT9290F becomes transparent after curing

- High reliability that withstands heat cycle tests (-40 to 85°C)

- High heat resistance (260°C) that withstands solder reflow processing

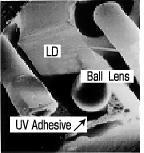

[Usage example] Fixing micro ball lenses

Image diagram

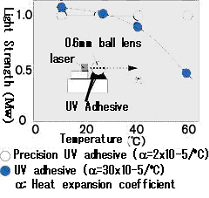

Temperature characteristics of LD module

Characteristic value

| model number [main component] |

viscosity (mPa・S) |

Curing conditions [Irradiation intensity, time] |

cure shrinkage (%) |

Glass-transition temperature Tg (°C) |

coefficient of thermal expansion (ppm/°C) |

Adhesion strength (kgf/cm2) |

Features |

|---|---|---|---|---|---|---|---|

| AT4291A [Epoxy] (*1) |

25,000 | 100mW/ cm2 10 minutes |

2 | 206 | 23 | >116 | low viscosity |

| AT9290F [Epoxy] (*1) |

45,000 | 100mW/ cm2 10 minutes |

1 | 140 | 31 | >200 | Transparent after curing (Large curing depth) |

| AT3862P [Epoxy] (*1) |

180,000 | 100mW/ cm2 10 minutes |

0.5 | 195 | 20 | >210 | Small cure shrinkage high viscosity |

| AT3916P [Epoxy] (*1) |

36,000 | 100mW/ cm2 10 minutes |

0.9 | 233 | 18 | >220 | low viscosity |

The characteristic values in the table are sample measurement values, not guaranteed values.

close up

close up