Notice of Termination of Sales of Replacement Parts and Repair Services for Optical Connector Polishing Machines "ATP-2200" and "SCP-241"

We would like to inform you that the following products that you are using regularly have been discontinued. Notice of discontinuation of ATP-3000 polishing machine

Capable of polishing up to 96 terminals of LC connector Released new optical connector polishing machine "ATP-3200"

- Improved maintainability while maintaining the advantages of the independent pressurization system -

feature

High polishing first-run rate

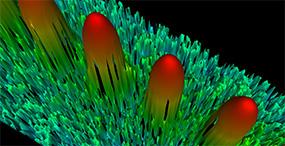

The original polishing trajectory achieves a high polishing straight-through rate (yield).

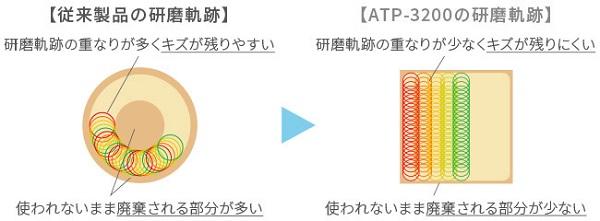

In the conventional rotation-revolution polishing machine, all the connectors that are polished at the same time pass through the same place on the polishing film. The connector end-face quality has been affected. With the ATP series polishing machine, the polishing trajectory only overlaps adjacent connectors, so even if foreign matter is present, other connectors will not be affected. This unique polishing trajectory mechanism achieves an unprecedented high straight-line polishing rate for connector end face appearance quality.

Furthermore, with the ATP-3200, this polishing trajectory can be adjusted by connecting to a PC, so even in special polishing, it is possible to optimize it according to the polishing target and specifications.

low cost

By cutting the polishing film in a square shape instead of a circle, making it possible to polish mainly in a straight line in addition to the conventional rotation-based polishing trajectory, Minimize the amount of wasted parts.

No rough diamond polishing process required

Furthermore, in the polishing jig for single-core connectors such as SC, the independent pressurization method *1 This eliminates the need for a rough diamond polishing process to adjust the variations in connectors and ferrules. For this reason, low-reflection PC polishing of single-core connectors can be completed in just three steps: (1) adhesive removal, (2) fine diamond, and (3) ADS silica finishing.

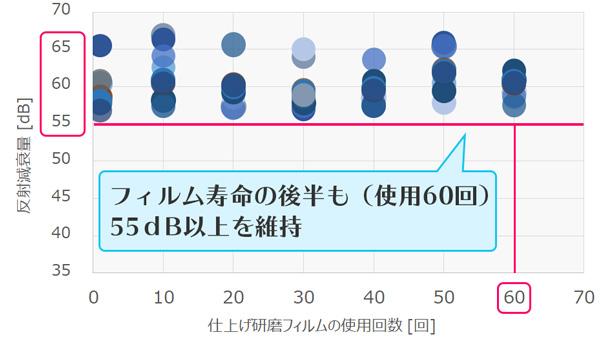

By using it together with the ADS series *2 final polishing film, it is possible to achieve both low cost and high polishing quality. The finishing film can now be used more than twice as many times as the conventional machine. Of course, it meets high performance polishing (55dB or more).

Duplex connectors *3 such as LC Duplex achieve both the number of times of use and performance more than double that of conventional models, just like single-core connectors.

| Number of LC Duplex | ADS-NEXT usage count | |

|---|---|---|

| ATP-3200 | 48 pairs (96 terminals) | 60 times |

| Conventional polishing machine | 26 pairs (52 terminals) | up to 30 times |

| Conventional low-cost polishing machine | 36 pairs (72 terminals) | up to 10 times |

Achieves both high-performance polishing (55 dB or more)

*1: A general optical connector polishing machine uses a batch pressurization method that fixes the connectors to be polished together. NTT-AT 's optical connector polishing machine adopts an independent pressurization method, and since each connector is pressurized individually, it completes with the appropriate amount of polishing for each connector, and it is a mechanism to prevent overgrinding. .

*2: This polishing film is highly rated at optical connector manufacturing sites around the world.

*3: Similar to LC Duplex, other duplex connectors can be polished at high performance and at low cost.

Simple operation, no skill required

| For single-core connector polishing | Insert the connector into the polishing jig and lock the pressure mechanism all at once! No tricks or tricks required. |

|---|---|

| For multi-core connector polishing | Since it is fixed from two directions, anyone can polish without tilting the polishing surface. |

| For fiber array and PLC polishing | Stable attachment by the core structure achieves stable polishing quality. |

In addition, no special additional equipment is required for polishing fiber arrays or PLCs. Easy-to-handle polishing film that can be easily polished in the same way as connectors. Furthermore, since most of the polishing films are the same as those for connectors, fiber arrays and connectors can now be run on the same polishing line.

program function

Prevent process mistakesThe time and speed of each polishing process and the stroke of the polishing trajectory can be set in advance for each object to be polished, such as SC/PC connectors and MT-24MM connectors. can be prevented.

Supports centralized control

With a PC (RS-232C/USB) connection, you can write process programs, adjust the polishing trajectory, and remotely operate the machine. This makes it possible to support centralized control along with the development of the production process, such as line automation by connecting polishing machines.

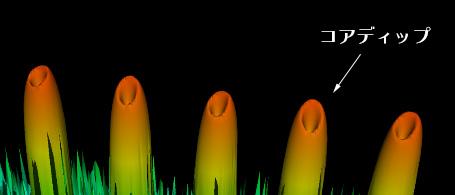

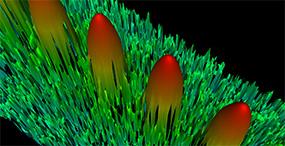

MPO also achieves high-performance polishing without core dip

Core dip affects return loss. Eliminating core dipping is the key to improving polishing performance.

It supports many optical fibers such as OS series including OS2, OM series including OM5, SMF-28, GI50, GI62.5.

Example of polishing without core dipping

Specifications and polishing examples

Specification

| ATP-3200 | |

|---|---|

| External dimensions | 370W x 430D x 300H (mm) |

| Weight | about 25 kg |

| power supply | AC 100 to 240V |

| power consumption | 240W |

Polishing example (ATP-3200)

| Polishing number (maximum) | 96 pieces | LC-Duplex |

|---|---|---|

| 48 pieces | SC Ferrule, LC Ferrule, MU Ferrule, Simple MU Ferrule SC/PC Plug, SC/APC Plug, FC/PC Plug, FC/APC Plug, LC/PC Plug, LC/APC Plug, MU/PC Plug MT, MPO, MT-RJ Ferrule, Fiber-Array (1-32ch) |

|

| 6 to 22 | Fiber-Array (the number of attachments differs depending on the size) | |

| Number of processes (recommended) | 3 steps | SC, FC, MU, LU (PC, APC) |

| 4 processes | MT, MPO & MT-RJ, Fiber-Array |

Abrasive properties

For single core PC polishing

| Curvature radius (mm) | Convex sphere eccentricity (μm) | Fiber pull (μm) |

|---|---|---|

| 10-25 | <50 | <0.05 |

For multi-center flat polishing

| type | RX (mm) | RY (mm) | angle (degrees) |

|---|---|---|---|

| MT (0°) | >2000 | >5 | 0±0.2 |

| MT (8°) | >2000 | >5 | 8±0.2 |

Jig list

for single core

| Jig name | Mounting number | Corresponding connector | Model | |

|---|---|---|---|---|

Independent pressure type plug/ferrule combined use

|

24 | Ferrule | SC, FC | ATP-3200-AZ0001 |

| LC, MU | ATP-3200-AZ0005 | |||

| plug | SC | ATP-3200-AZ0007 | ||

| SC/APC Conical | ATP-3200-AZ0009 | |||

| FC | ATP-3200-AZ0002 | |||

| FC/APC Conical | ATP-3200-AZ0010 | |||

| LC | ATP-3200-AZ0006 | |||

| LC/APC Conical | ATP-3200-AZ0008 | |||

| 48 | LC-Duplex | ATP-3200-AZ0018 | ||

for multi-core

| Jig name | Maximum number of attachments | Corresponding connector | Model | |

|---|---|---|---|---|

For independently pressurized ferrule

|

24 | Ferrule | MT (0°) | ATP-3200-AZ0003 |

| MT (8°) | ATP-3200-AZ0013 | |||

| MT-RJ (0°) | ATP-3200-AZ0012 | |||

close up

close up