Solvent-based high refractive index resin

Characteristic

Characteristics table

| item | conditions | unit | #18210 |

NH660

|

NH706

|

||

|---|---|---|---|---|---|---|---|

| solvent | - | - | PGME | PGME | PGME/PGMEA | ||

| Properties before curing | viscosity | E-type viscometer: 25 °C | mPa s | 15 | 5 | 4 | |

| Curing conditions | Pre-bake | - | - | 115°C 1min | 120°C 1min | 110°C 1min | |

| UV irradiation amount |

UV lamp : 365 nm intensity |

- |

100 mW/ cm2 |

300 mW/ cm2 180 seconds (UV-LED light source) |

300 mW/ cm2 |

||

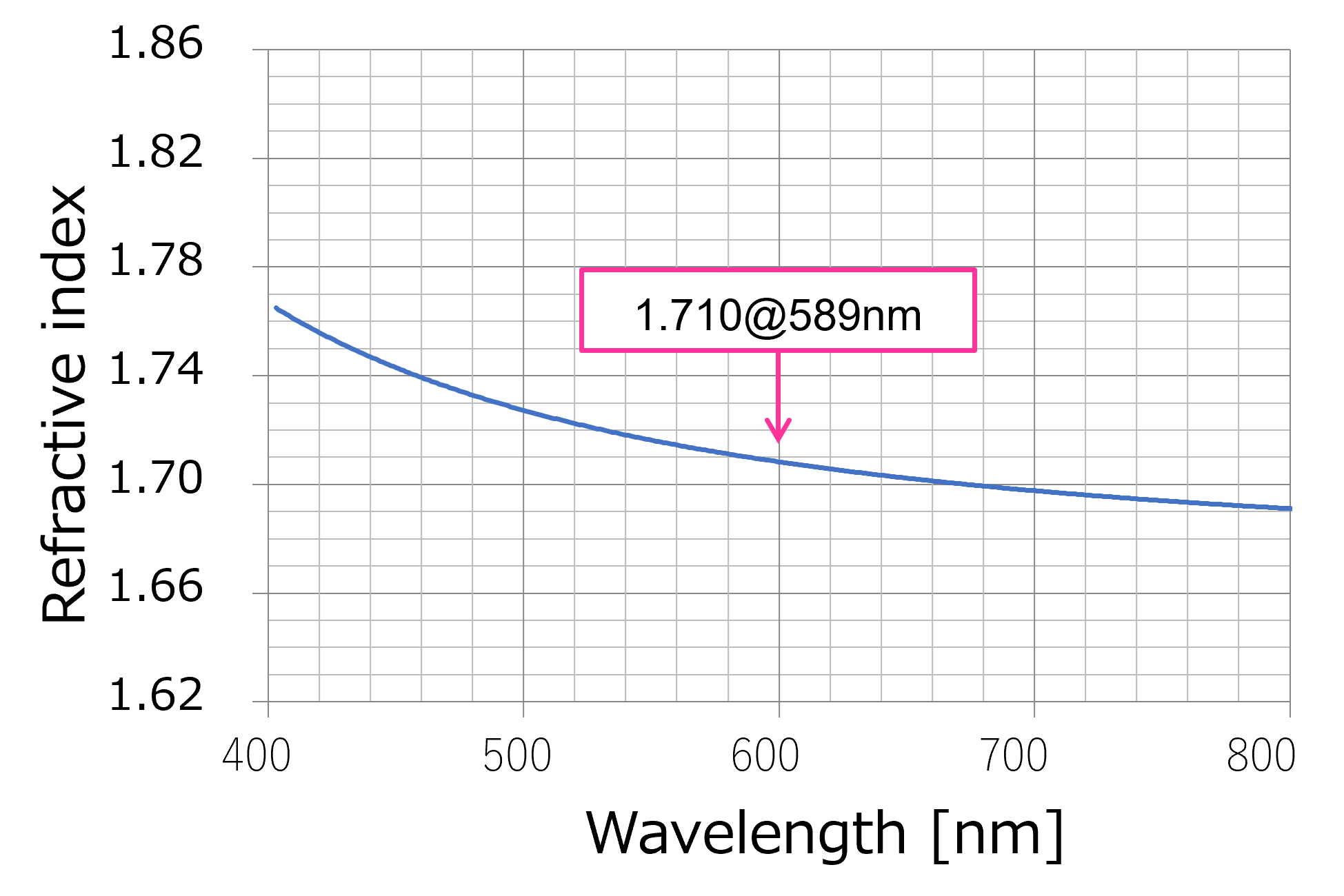

| Propertiesafter curing | refractive index | sodium d line | λ=589 nm | 1.725 | 1.710 | ||

| haze | Thickness: 1 μm | % | < 0.1 | < 0.1 | < 0.1 | ||

| Glass-transition temperature | Dynamic viscoelasticity: tanδ max | °C | 100 | 125 | 195 | ||

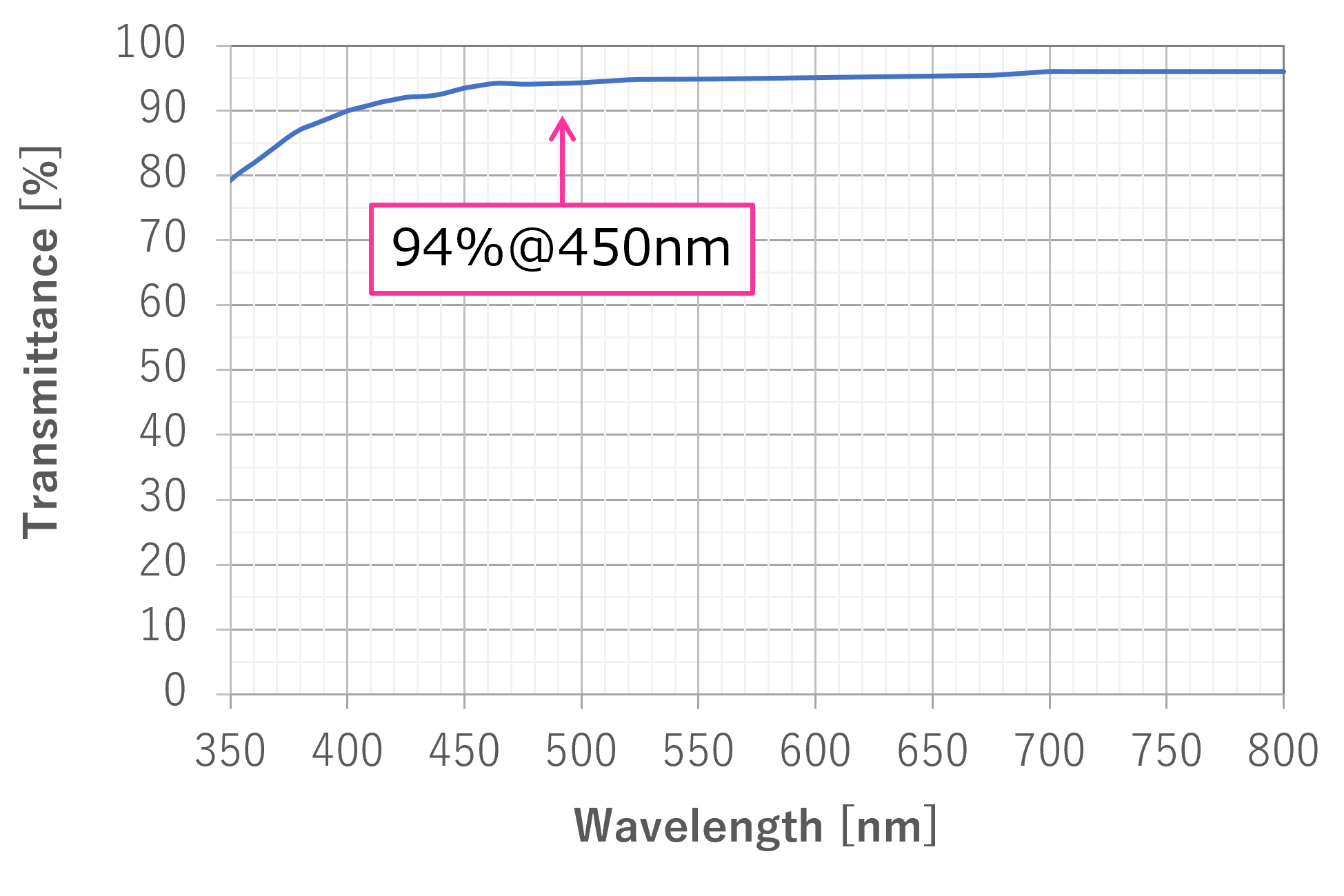

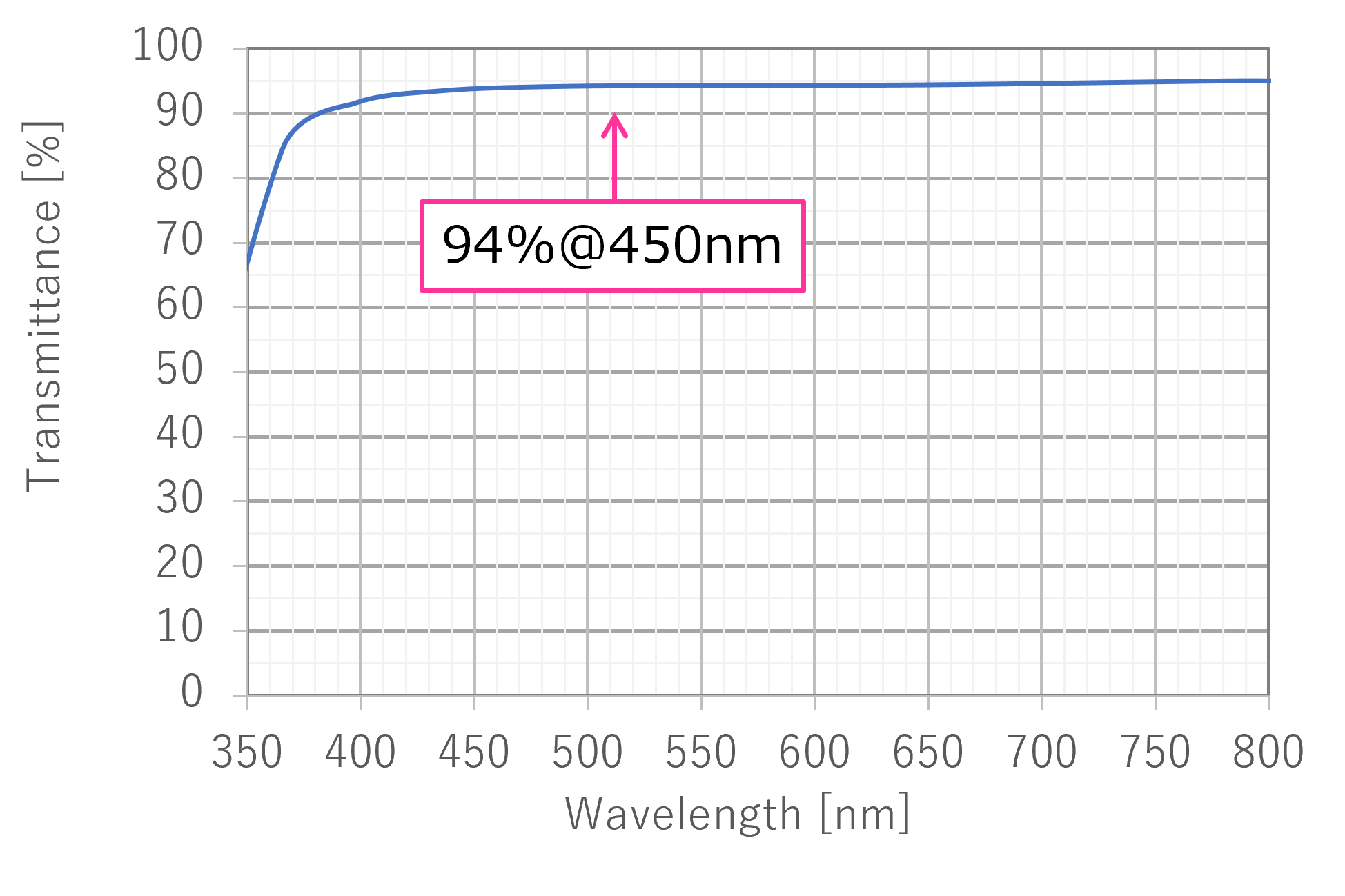

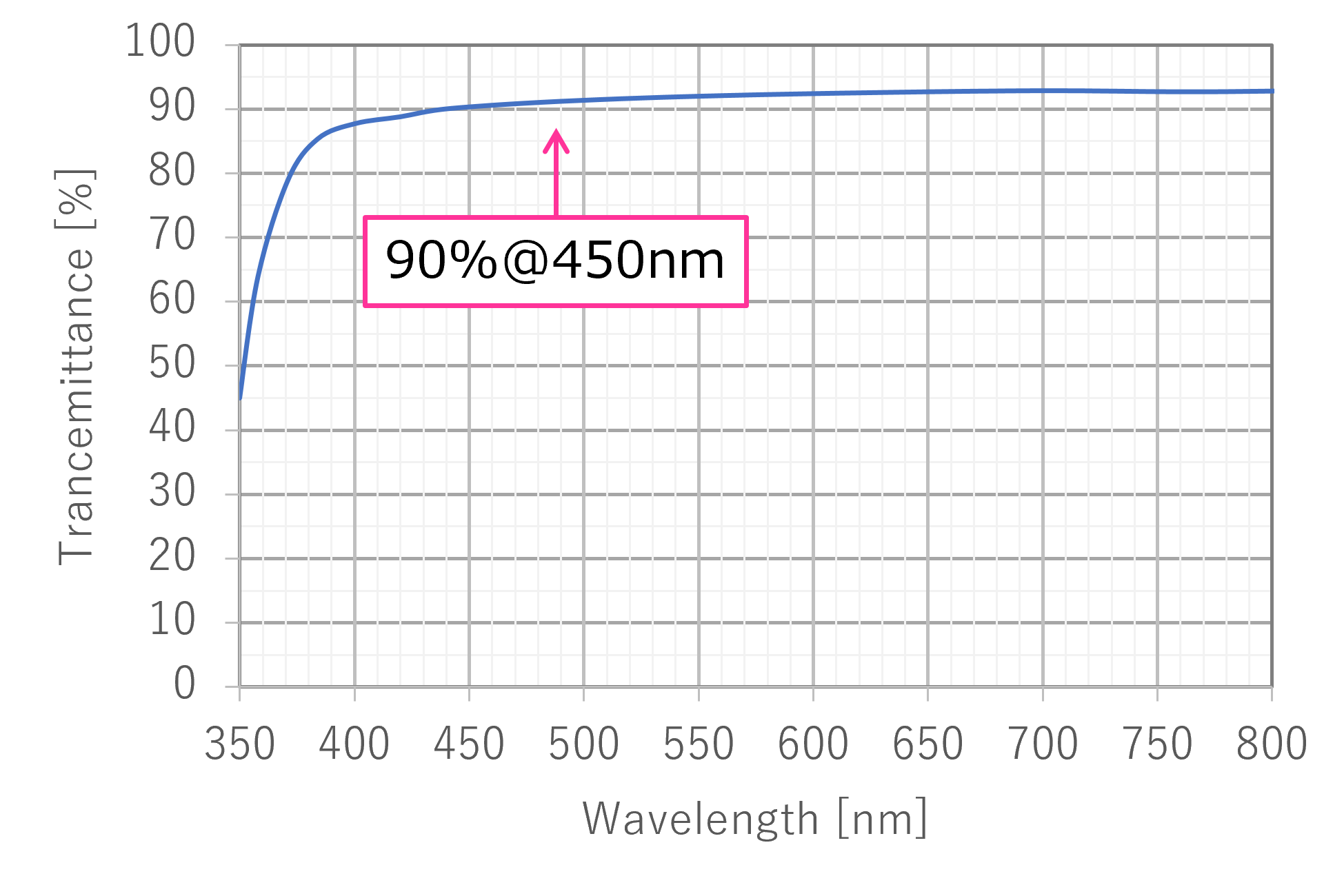

| transmittance |

Thickness:1 μm |

% | 94 | 94 | 90 | ||

The data are only measured values, not guaranteed values.

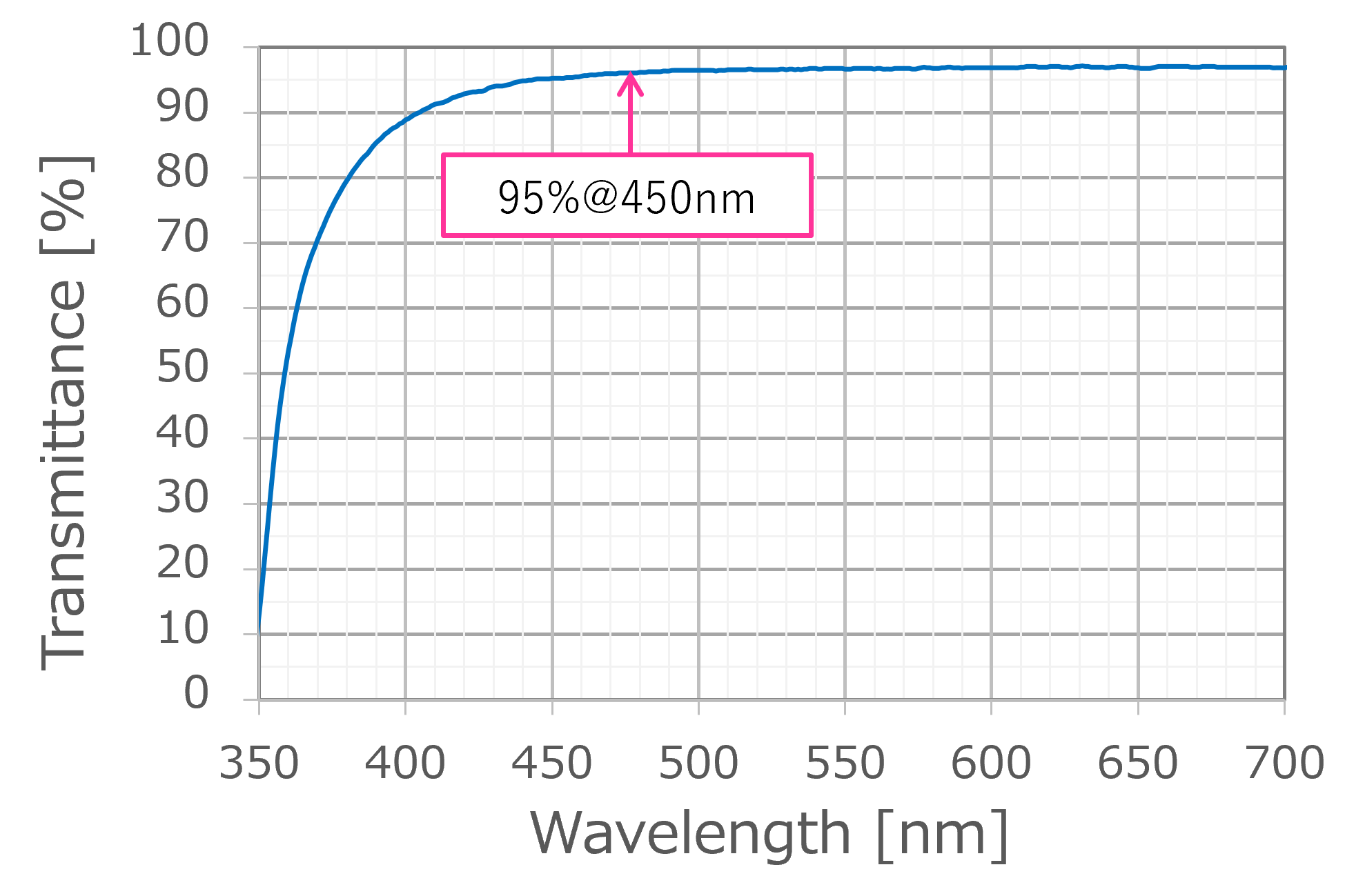

optical properties

Light transmittance: Indicates the light transmittance of a sample with a thickness of 1 μm. Values include return loss.

Application example

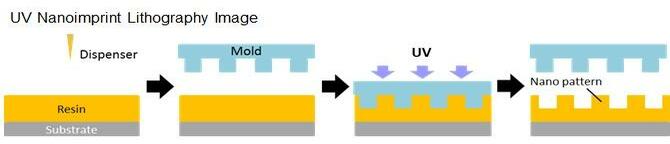

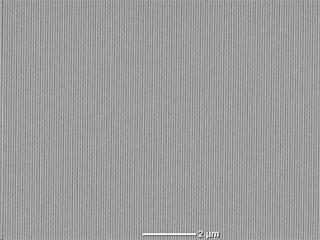

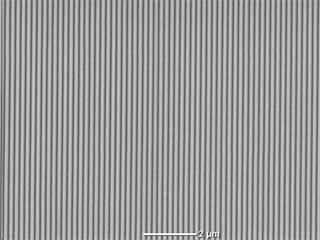

nanoimprint

This is a processing technology in which a stamper with a nanoscale uneven pattern is pressed against a resin-coated substrate and then heated or light-cured to transfer the uneven pattern to the resin.

It is attracting attention as a next-generation mass production technology because it can be processed easily and at a low cost compared to conventional nanoscale processing technology.

This resin is a nanoimprint resin with a high refractive index, and can be applied to fabricate functional precision patterns with a high refractive index.

Conceptual diagram of nanoimprint fabrication

Width: 100 μm, Depth: 100 nm

Width: 0.5-5um, Depth: 350nm

Solvent-free high refractive index resin

Characteristic

Characteristics table

| item | conditions | unit | Acrylic | epoxy | ||||

|---|---|---|---|---|---|---|---|---|

| #18165 | #18247 | #6205 | E3754 | |||||

| Properties before curing | viscosity | E-type viscometer: 25°C | mPa s | 9 | 138 | 20 | 1,200 | |

| Curing conditions | UV irradiation amount |

UV lamp : 365 nm intensity |

metal halide lamp |

10 mW/ cm2 |

100 mW/ cm2 60 seconds |

100 mW/ cm2 |

10 mW/cm2 600 seconds |

|

| Propertiesafter curing | refractive index | sodium d line | λ=589 nm | 1.675 | 1.710 | 1.720 | 1.603 | |

| haze | Thickness: 1 μm | % | < 0.1 (Thickness: 50 μm) |

< 0.1 (Thickness: 50 μm) |

< 0.1 (Thickness: 90 μm) |

- | ||

| Glass-transition temperature | Dynamic viscoelasticity: tanδ max | °C | 113 | 125 | 68 | 73 | ||

| transmittance |

Thickness:1 μm |

% | 94 | 95 | 72 | 92 | ||

| Shrinkage factor | % | 9 | 7 | 8 | 5 | |||

| hardness | Shore D | D67 | D78 | D70 | D76 | |||

| adhesive strength |

kgf/cm2,

glass/glass

|

>48 | - | 35 | >280 | |||

The data are only measured values, not guaranteed values.

optical properties

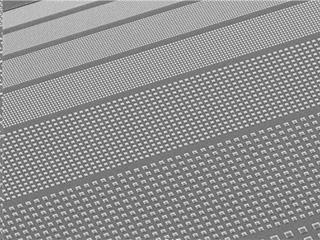

Application example

- resin lens

- thick film

close up

close up