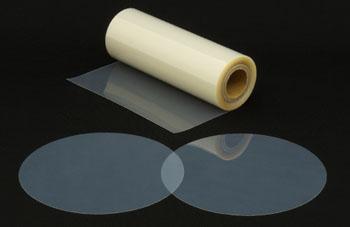

ADS Rubber

Polishing pad for ADS film

Features

Maximizes the performance of ADS film.

ADS rubber is a polishing pad optimized for ADS finish polishing film *.

The ADS film performance can be improved by simply changing the polishing pad to ADS rubber, while maintaining the current polishing process conditions.

*Can also be used with ADS-NEXT and ADS-NEO series.

Effect

Improvement of reflection attenuation

Simply changing to ADS rubber reduces fiber penetration by ADS film and improves reflection attenuation.

Longer life of ADS film

Changing to ADS rubber improves the polishing life of the ADS film and reduces the frequency of polishing film replacement.

Longer life of polishing pad

ADS rubber offers longer service life with improved wear and deterioration resistance, reducing the frequency of polishing pad replacement.

Specifications

ADS Rubber

| Standard Size | Disk type: 127 mm (5 inch) dia. |

|---|---|

| Standard thickness (mm) | 5 |

| Rubber Hardness (Hs) | 65 , 70 , 80 , 85 |

Examples of improved polishing performance

ADS film polishing life

Conventional product

15 times

ADS Rubber

25 times

Reflection attenuation

Conventional product

-53 to -56 dB

ADS Rubber

-55 to -58 dB

Fiber thrust

conventional product

SC/PC: 0 to -30 nm

LC/PC : -20~-40nm

ADS Rubber

SC/PC: 0 to -20 nm

LC/PC : -10~-30nm

*Conditioned Polisher (Polishing machine manufactured by BULLS) Polishing Step (conditions set by the company)

*This data is an example of polishing results, which are influenced by various factors such as polishing conditions, the polishing machine used, and the shape of the ferrule.