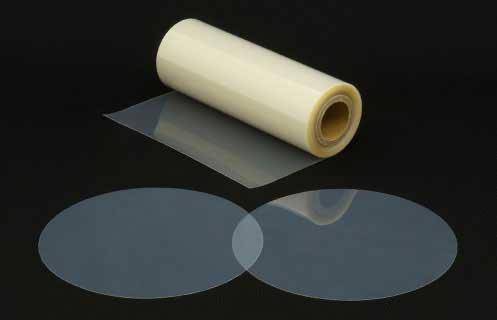

Long Life Polishing Film ADS series

Final Polishing Film

Benefits / Features

Ideal for the final polish of optical connector end face

Polishes optical connector end face without scratches or residues. Also, there is no adhesion of polishing film binder or silica grains.

Delivers the same long life as ADS film.

Has stable polishing force while both maintains final finish performance and achieves an extended life-span. Attains a high performance polish with distilled water.

A great improvement for the problem of fiber indentation

A sharp improvement in the indentation problems that occur especially in φ1.25mm ferrule, from repeated use polishing. Even after many usages it can still protect against sudden occurrences of fiber indentation.

Final Polishing Film ADS & ADS-NEXT Inquiry

Specifications

Specifications of ADS Series

| Type | ADS Series Final Polish Silica Film |

|---|---|

| Standard Sizes |

Disk type: 127mm (5inch)dia. (100pcs/set) Roll type: 140mm (5.5inch)×12m (1 roll/set) |

| Film Color |

ADS-NEXT: Colorless, translucent (Disks have the “NEXT” stamp in the center) ADS: Colorless, translucent (Disks have the “ADS” stamp in the center) |

| Base Thickness | 75μm (3mil) |

| Compatible Ferrule |

2.5mm diameter zirconia ferrule 1.25mm diameter zirconia ferrule |

Polishing Film Lineup

ADS

Now used at 500+ companies! Top selling final polishing film worldwide.

Can be used for almost any polishing machines, polishing process, and connectors.

| Return Loss | -52~-56dB(PC)、-80dB or more(APC) |

|---|---|

| Polishing Liquid |

EtOH20% water recommended

(Distilled water can also be used)

|

| Polishing Machines | ATP-3200, Center pressure (OFL) type, square pressure (SFP) type |

ADS-NEXT

Final polishing film that can prevent fiber indentations.

Prevent fiber indentations even used multiple times. Best when used with ATP-3200.

| Return Loss | -57~-60dB(PC)、-80dB or more(APC) |

|---|---|

| Polishing Liquid |

Distilled water

|

| Polishing Machines | ATP-3200, Center pressure (OFL) type |

NEW ADS-NEO

Final polishing film that prevents fiber indentations from high pressurized polishing.

Next generation final polishing film for high pressurized polishing.

| Return Loss | -56~-59dB(PC)、-80dB or more(APC) |

|---|---|

| Polishing Liquid |

Distilled water

|

| Polishing Machines | ATP-3200, square pressure (SFP) type |

Polishing Conditions (LC/UPC)

Polishing Machine: Center pressure (OFL) type| Return Loss | Polishing Film | Time (sec) | |

|---|---|---|---|

| 1 | Polishing LiquAdhesive Removalid | AAS-WA09A-R140-12 | 30 |

| 2 | First Polish | AAS-DM09-127 | 30 |

| 3 | Second Polish | AAS-DM01-127 | 60 |

| 4 | Final Polish | ADS-NEXT-127 | 30 |

| Return Loss | Polishing Film | Time (sec) | |

|---|---|---|---|

| 1 | Polishing LiquAdhesive Removalid | AAS-WA09A-R140-12 | 30 |

| 2 | First Polish | AAS-DM09-127 | 25 |

| 3 | Second Polish | AAS-DM01-127 | 35 |

| 4 | Final Polish | ADS-NEO-127 | 25 |

Polishing Machine:ATP-3200

| Return Loss | Polishing Film | Time (sec) | |

|---|---|---|---|

| 1 | Polishing LiquAdhesive Removalid | AAS-WA09A-R140-12 | 15+39 |

| 2 | First Polish | AAS-DM09-R140-12 | 90 |

| 3 | Final Polish | ADS-NEXT-127 | 60 |