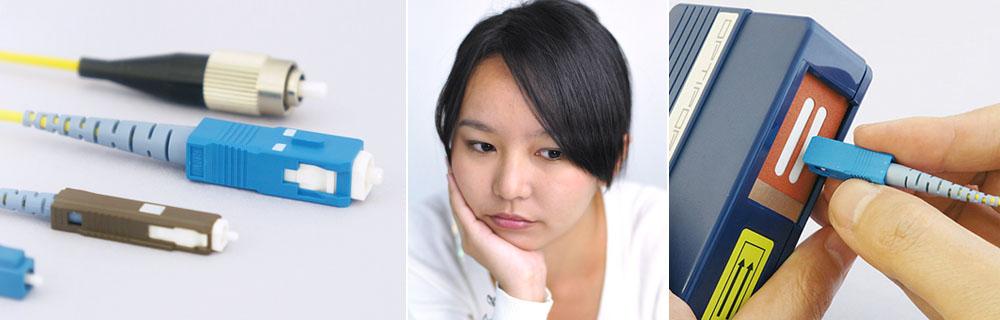

Why do I need to clean and inspect the end face now?

The Impact of Optical Connector End Face Contamination and How to Prevent it

Features

Because the optical fiber core, which transmits the communication light signal, has a small diameter of only 10 microns, even a small spot of contamination, which may be invisible to the naked eye, may affect transmission performance and cause communication failure.However, since the optical connector end-face is exposed, it is difficult to avoid it being contaminated.

To avoid communication failure due to contamination, it is necessary to clean the optical connector end-face just before making the connection.

|

|

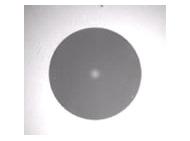

| Clean optical connector end-face | Contaminated (grease from hands) optical connector end-face |

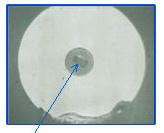

In recent years, the power of optical communication light has become stronger.

Since the communication light is confined in an extremely small core of 10 microns diameter, its power density is very high. If some contaminating substance adheres to the core, it may burn and the heat may melt the core.

|

| Photo showing a core that has melted as a result of a contaminated substance on the end-face being irradiated with a high power laser. |

A detailed document is available for your reference.

Why do I need to clean and inspect the end face now? Inquiry

Technical Document

“The Impact of Optical Connector End-Face Contamination and How to Prevent It”

This document has been well received by optical connection operators and contractors as a useful optical connector reference material.

"The Impact of Optical Connector End-Face Contamination and How to Prevent it"

--Why do I need to clean and inspect the end face now?--

Why do I need to clean and inspect the end face now? Inquiry

Ver.1.3

Ver.1.3